Keynote – Passive RFID Wireless Sensor Technology

Prof. Donald C. Malocha, University of Central Florida

Opening Plenary, 8:30am

Wednesday, May 4, 2016

Surface acoustic wave (SAW) technology is attracting serious interest for a broad range of sensor applications, especially in aerospace and health monitoring systems. Many applications have very challenging requirements: maintenance-free (no battery), no external power (scavenging or external power source), reliable life-cycle (years in a wing structure or hours in an engine exhaust), light and small, etc. A short list of system specifications may include simultaneous multi-sensor interrogation/reception, wireless, passive, radiation hard, and range of several centimeters to 100’s of meters. The sensors should be small, rugged, provide RFID on chip, operate at cryogenic to high temperature, and differing embodiments can provide temperature, gas, pressure, strain, and others. The convergence of precise SAW modeling and synthesis, advanced SAW materials and embodiments, fast and cheap RF components and high speed analog to digital conversion and high speed processing has ushered in new opportunities for SAW sensor technology applications. This technology concurrence permits RFID, multi-parameters, high-speed signal acquisition, and advanced signal processing, here-to-fore not possible.

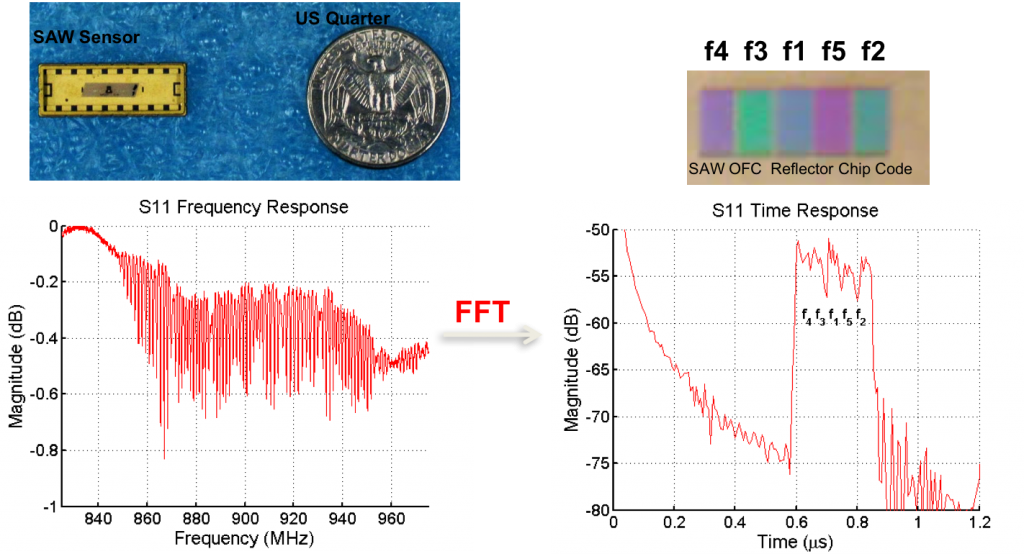

This presentation will discuss SAW passive, wireless multi-sensor systems (PWS) under development for the past several years at the University of Central Florida. Several 915 MHz orthogonal frequency coded (OFC) SAW multi-sensor systems are presented; including experimental data. The OFC SAW sensors, using both frequency diversity and pulse position reflectors to encode the device ID, and will be briefly contrasted to other embodiments. The transceiver hardware implements a synchronous correlator approach, and post processing and matched filter techniques of the received signal are used to extract the sensor information. Critical device and system parameters addressed include encoding, operational range, SAW device parameters, post-processing, and antenna-SAW device integration. The current system is based on a software design radio approach that provides great flexibility for many sensor types, future enhancements and diverse applications.

Initial work on orthogonal frequency coded (OFC) SAW devices for RFID and communication began in 2000, and the first publication on SAW OFC was in 2004. The implementation of OFC in a SAW structure provides the greatest flexibility in time, frequency and code diversity. This adaptability has advantages in a multi-sensor system for identification and sensor accuracy, which will be presented. The device and systems to be discussed are based on an operational center frequency of 915 MHz. The 5 chip OFC reflectors are used for encoding each device on YZ LiNbO3 and the devices are connected to a folded dipole antenna for reception and re-transmission of the interrogation signal. Several sensor types using the OFC SAW platform will be presented and videos will be shown demonstrating a variety of sensors, including temperature, closure, ranging, and room-temperature, rapid-reversible, hydrogen gas sensing; all using the same transceiver. Recent NASA-KSC test results of delivered sensors and systems will also be included. PWS SAW technology has verifiable operational prototypes, and integration into applications is beginning. Future work and projections for the PWS technology regarding frequency, bandwidth, range, applications, transceivers, and system hardware will be discussed.